A Comprehensive Guide to the Sorts Of Ceramic Finish on the Market

Ceramic finishes have actually emerged as a critical option throughout numerous sectors due to their distinct residential properties and applications. As we discover the distinct characteristics and applications of these finishings, the implications for performance and durability end up being progressively obvious, increasing concerns about which type could ideal fit your demands.

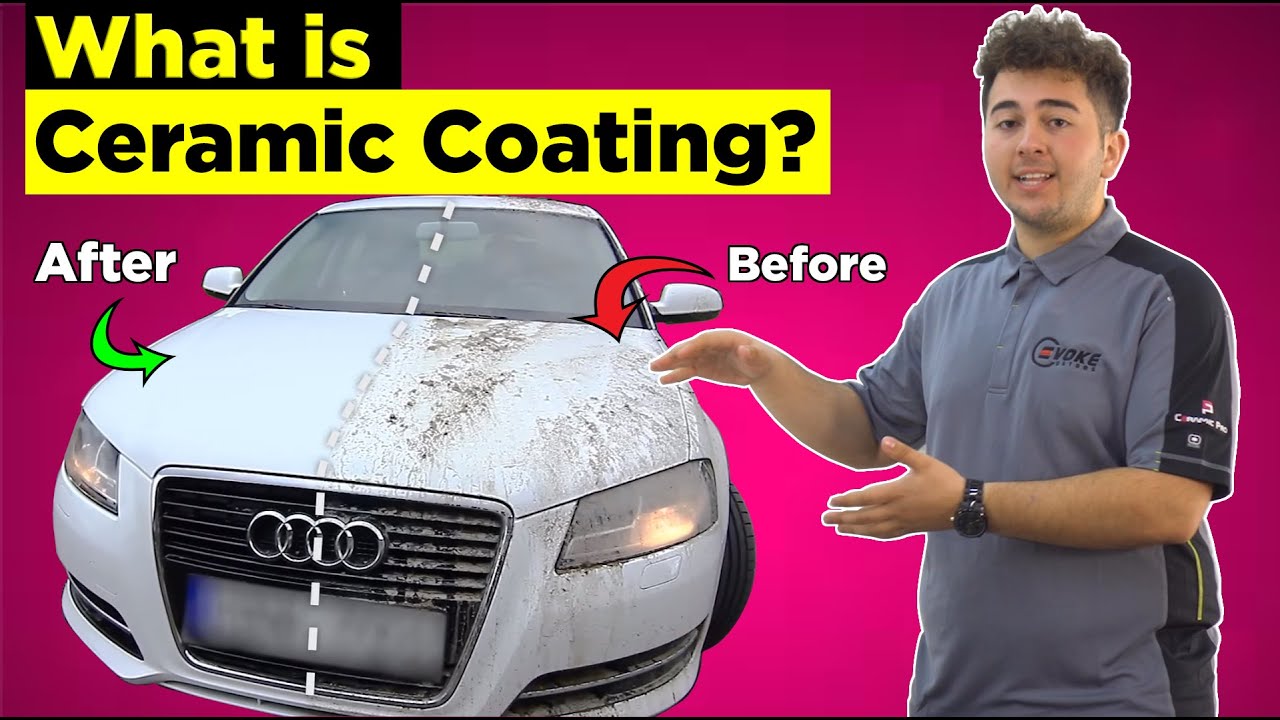

Recognizing Ceramic Coatings

Ceramic coverings are sophisticated safety options that have actually gotten appeal in different markets, especially in vehicle and aerospace applications. These layers contain a fluid polymer that, when healed, creates a long lasting, hydrophobic layer externally of the substrate. This layer offers enhanced resistance to environmental impurities, UV radiation, and chemical direct exposure, consequently prolonging the life and aesthetic allure of the underlying product.

The essential component of ceramic coverings is silica, which contributes to their solidity and longevity. The application procedure normally includes surface prep work, application of the finish, and curing, which can be achieved via warm or UV light. Once healed, ceramic finishes display extraordinary bonding residential or commercial properties, enabling them to adhere strongly to a selection of surfaces, consisting of metals, plastics, and glass.

In enhancement to their protective functions, ceramic finishings also supply simplicity of maintenance. Their hydrophobic nature lowers the adherence of dirt and grime, making cleansing simpler and much less frequent. On the whole, the adoption of ceramic layers stands for a significant improvement in surface defense modern technology, supplying both visual and practical advantages across several sectors.

Sorts Of Ceramic Coatings

Numerous types of ceramic finishes are available, each created to fulfill particular efficiency requirements and applications. The most typical kinds include:

Silica-based Coatings, these finishings largely consist of silicon dioxide and are understood for their durability and chemical resistance. They are commonly made use of in automotive and industrial applications.

Titanium Dioxide Coatings: Distinguished for their photocatalytic buildings, titanium dioxide finishes are typically used in settings where self-cleaning and antifungal properties are preferable, such as in building materials and vehicle finishes.

Zirconia Coatings are characterized by their high-temperature stability and thermal resistance, zirconia finishes are made use of in applications such as turbine engines and high-performance automotive components.

Alumina Coatings, Displaying outstanding firmness and thermal security, alumina finishes are regularly made use of in wear-resistant applications, consisting of reducing devices and commercial machinery.

Hybrid Coatings:Integrating the buildings of numerous products, hybrid finishings use improved performance characteristics, making them suitable for unique and requiring applications.

Each sort of ceramic layer offers distinctive objectives, allowing customers to pick one of the most proper option based on specific ecological problems and performance demands.

Advantages of Ceramic Coatings

Along with resilience, ceramic coverings provide excellent hydrophobic residential or commercial properties, permitting very easy cleansing and maintenance. This water-repellent nature decreases the adherence of dust, gunk, and other impurities, which can extend the aesthetic appeal and functionality of the surface. Ceramic layers can substantially improve thermal resistance, making them perfect for applications that sustain high temperatures.

Ceramic coatings can add to power efficiency by mirroring warm, which is specifically advantageous in commercial and auto settings. Overall, the various advantages of ceramic coverings make them a beneficial financial investment for numerous applications, making certain optimal efficiency and defense.

Application Refine

When using ceramic finishings, a precise method is essential to attain optimum results. A tidy surface makes sure proper attachment of the finish.

As soon as the surface area is prepped, the following step is to use the ceramic covering. This can be done utilizing an applicator pad or a microfiber fabric, making sure even insurance coverage. It is critical to function in small areas to maintain control and protect against premature curing - Ceramic Coating Denver. The layer must be applied in slim layers, as thicker applications can result in irregular surfaces.

After application, the coating needs a specific healing Click This Link time, generally varying from a few hours to a full day, relying on the product. Throughout this moment, it is important to stay clear of exposure to wetness or impurities. Finally, a gentle buffing might be necessary after treating to improve the gloss and get rid of any type of high areas. Adhering to these steps carefully will maximize the performance and longevity of the ceramic finishing, giving a resilient safety layer for the surface area.

Maintenance and Longevity

To ensure the long life and efficiency of a ceramic finishing, regular upkeep is necessary. Ceramic finishes, known for their durability and site link safety high qualities, require certain care regimens to maximize their lifespan and performance.

Along with routine cleaning, periodic examinations are essential. Seek signs of wear or damages, such as hydrophobic residential or commercial properties lessening or surface flaws. A light gloss might be applied to revitalize the finish without removing it away. if necessary - Ceramic Coating Denver.

Moreover, the application of a booster spray can boost the coating's hydrophobic impacts and restore its gloss. This is specifically beneficial for finishes that have actually remained in usage for a prolonged period. Eventually, by adhering to these upkeep techniques, one can considerably prolong the life of a ceramic layer, ensuring that it continues to supply ideal defense versus ecological variables and keep the visual allure of the lorry.

Verdict

In final thought, ceramic coverings stand for a versatile service for a series of applications, offering a range of kinds such as silica, titanium dioxide, alumina, and zirconia. Each kind offers distinct advantages, consisting of durability, self-cleaning residential properties, high-temperature security, and wear resistance. The application process and continuous upkeep play essential roles in optimizing the long life and efficiency of these finishes. Overall, ceramic finishings add dramatically to boosting the resilience and performance of different surfaces across several markets.

Ceramic coatings have actually arised as an essential service across numerous sectors due to their special residential or commercial properties and applications.Ceramic finishings are sophisticated protective remedies that have actually site link acquired popularity in numerous markets, particularly in automotive and aerospace applications. Ceramic finishes can considerably enhance thermal resistance, making them excellent for applications that withstand high temperatures.

On the whole, the many advantages of ceramic layers make them a useful investment for numerous applications, guaranteeing optimum performance and defense.

In final thought, ceramic coatings stand for a versatile option for a range of applications, using a variety of kinds such as silica, titanium alumina, dioxide, and zirconia.